Resources at Your Fingertips

An entire wing of the Agricultural Science Building complex is devoted to the Engineering and Technology Department. It is conveniently connected via a glass hallway to the main part of the building where most of the other courses in the College of Agriculture, Food and Environmental Sciences are taught. Just across the sidewalk on the north side of the Agricultural Science Building is the new Science and Technology Building, which is scheduled to open in January 2026. SciTech will house engineering support programs, including physics, chemistry and biology.

Arguably the best resource is our faculty! At UWRF, all courses, including the laboratory sections, are taught by faculty, not graduate students or teaching assistants as is often the case at larger universities. Our experienced educators have real-world experience so you'll be learning from the best!

Explore below to see some of the facilities you'll be learning in at UWRF.

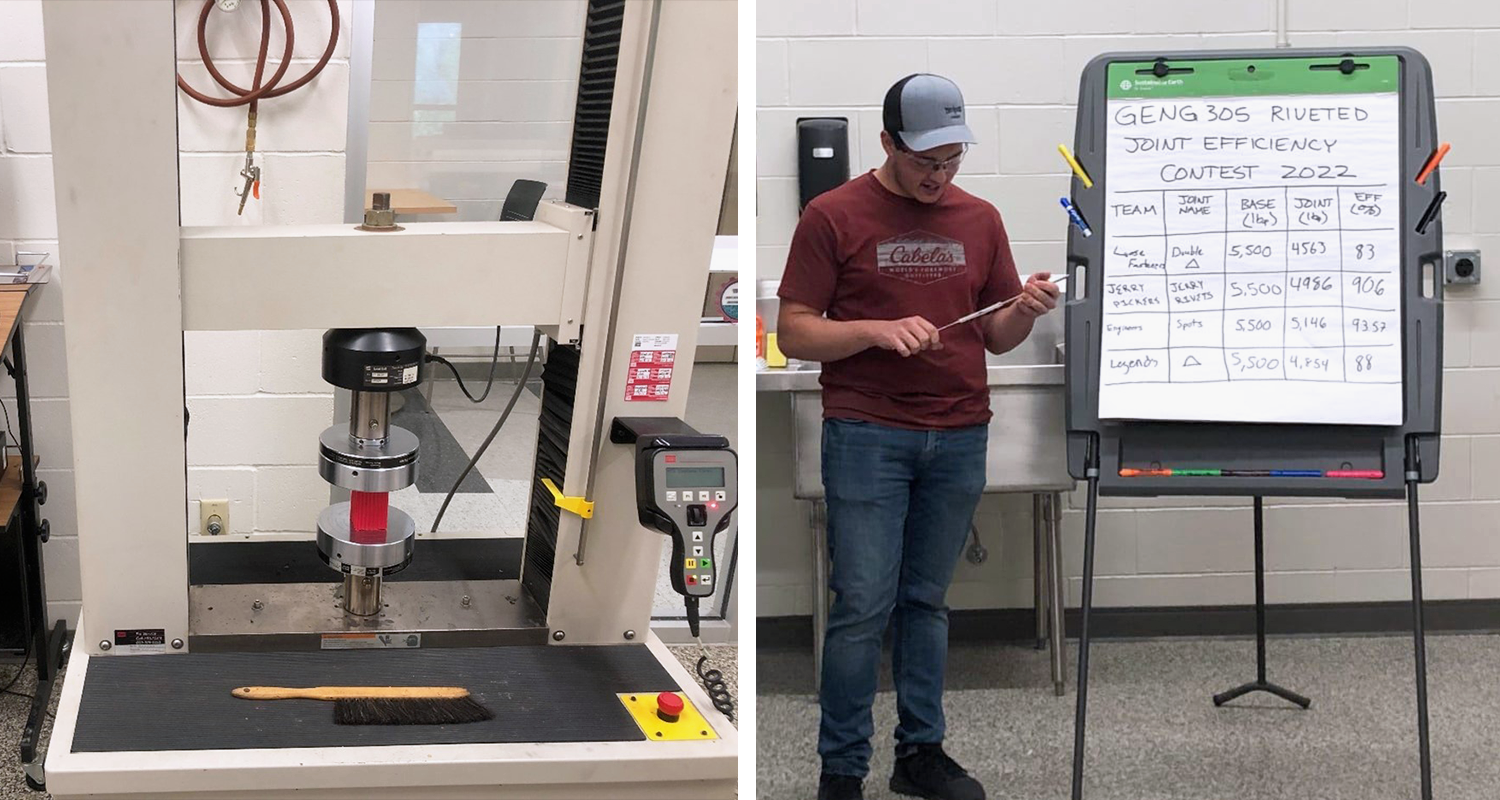

Testing Lab

Our testing lab is equipped with an MTS universal tester, a Phase II Rockwell hardness tester and an Olympus stereo microscope. Both engineering and engineering technology students gain hands-on skills measuring material properties and characterizing the microstructure of fractures (failures) in metals. With the universal tester, students can measure tensile stress, compressive stress, shear stress, strength of fasteners, effects of stress concentrators and even the tenderness of food!

Students in Machine Design Lab (GENG 305) get practical experience by designing, fabricating and measuring the strength of riveted joints, comparing actual strength and failure mode to theoretical. The team designing the strongest riveted joint wins a prize.

Wet Chemistry Lab

The wet chemistry lab houses a variety of equipment. Students can measure food properties using the rheometer, measure calorie content with a calorimeter, measure protein content, use high performance liquid chromatography (HPLC) to determine chemical composition and conduct freeze-drying (think astronaut ice cream!) and fermentation experiments. This lab is used in courses and for undergraduate research projects.

3D Printing Lab

Our 3D printing lab has both FDM (filament)-based and resin-based printers. We can print a variety of polymers, both rigid and flexible, as well as carbon fiber composites. Managed by students, this lab is very active, as we often work with other departments and faculty on projects. We recently created parts of animal anatomy for the UWRF Humane Handling Institute.

Soil and Water Engineering Lab

Our soil and water engineering lab features a 16 foot Armfield C4 multi-purpose flume with 3 inch x 10 inch cross section. This device allows students to perform hands-on experiments related to open channel flow like rivers and streams and explore the effects of flow rate, slope, riverbed characteristics and turbulence and how they might impact things like erosion. This device can also be used in a non-flowing mode to study diffusion of a pollutant. Other hands-on equipment in this lab include an internal pipe flow rig, soil sieve machine, soil grinders, a high-capacity compression tester for measuring the strength of concrete, a soil shear tester and many bench-top soil measurement instruments.

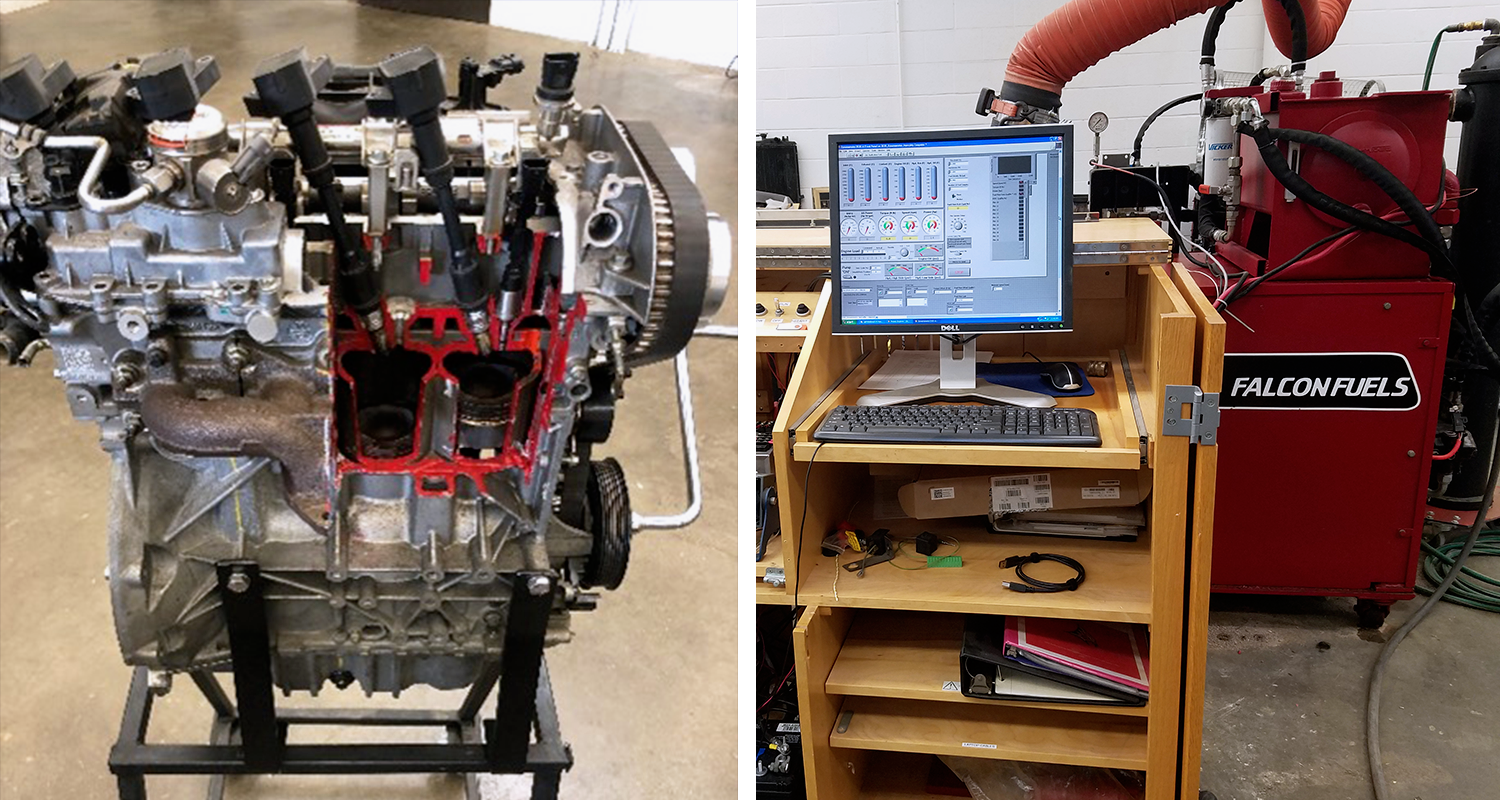

Engines and Fluid Power (Hydraulics) Lab

Our engines and fluid power lab features a wide variety of cut-away engines, including tier 4 diesel and GDI gasoline. Students are able to get their hands dirty as they disassemble, reassemble and test air-cooled gasoline engines and perform dynamometer testing on diesel engines. Students can set up and test a huge variety of hydraulic circuits using manual control valves all the way up to proportional solenoid and PID controlled circuits.

Electricity and Instrumentation Lab

This extensive laboratory gives students the ability to develop hands-on skills in soldering, bread-boarding circuits, setting up 120VAC and 220VAC circuits, using oscilloscopes, generating signals with function generators, creating LabVIEW programs, installing and testing strain gauges, fabricating thermocouple sensors, creating PLC ladder logic, reading data off of a CAN bus, designing and fabricating CAN bus modules and many other skills. Students learn skills and knowledge here that leads to careers in test engineering, off-road machine and vehicle design, systems troubleshooting and industrial PLC process design/installation/maintenance.

Wuethrich Family/Grassland Dairy Center of Excellence Dairy Plant

Students apply textbook theory and gain hands on experience in dairy processing at this new multi-million-dollar facility. Engineering skills developed in the classroom involving fluid mechanics, heat transfer and preservation processes are directly applied in the plant. Students can work part-time for the Falcon Creamery during the school year.

The network of pipes, valves, temperature sensors, process monitors, the control system for fluid flow, the heat exchanger and membrane systems are perfect for teaching processing engineering. Having access to a production environment, even on a small scale, is a real plus for our students!

UWRF Mann Valley Laboratory Farm

Just 10 minutes from campus, the Mann Valley Lab Farm is a great resource for hands-on, field-based classes and a wide range of undergraduate research projects on topics like agricultural and off-road machinery, environmental engineering, sustainability and robotics.